Traditional Balsamic Vinegar of Modena is a product renowned throughout the world for its unique flavor and exceptional qualities. There are several reasons why this delicacy is produced in Modena and its province: first of all due to the centuries-old tradition and the artisanal production techniques developed over the centuries, which are kept as real secrets. The black gold of Modena is in fact a precious and inimitable treasure for those who live in these areas and almost all families have barrels that are handed down from generation to generation: this certainly contributes to maintaining the authenticity of the famous condiment. But the production of Balsamic Vinegar of Modena is also and above all a question of climate.

Ideal climate and soil: these are the secrets of Balsamico.

The production of Traditional Balsamic Vinegar is a long and complex process that requires patience, experience and attention to detail. Modena producers strictly follow traditional standards and production methods which include the maturation of the vinegar in fine wooden barrels for a long period of time (at least 12 years) and the choice of local variety grapes (such as Trebbiano and Lambrusco ). The traditional Balsamic Vinegar of Modena is in fact protected by a Protected Designation of Origin (DOP), which guarantees that the product is made according to specifications of the Modena region.

On the other hand, the climate and soil of the Modena region provide ideal conditions both for the cultivation of grapes and for the subsequent production of Balsamic Vinegar. The calcareous soil and the temperate climate in fact favor the growth of the grapes, while the wide temperature variations that occur between winter and summer contribute to creating the unique aromatic profile of the vinegar (which we remember is formed not through thickening, but thanks to the top-ups that enrich the product with new aromas and characters from year to year).

In particular, balsamic vinegar factories are traditionally located in attics because this positioning protects them from humidity and provides ideal temperature conditions for the maturation of Balsamic Vinegar. Of course, attics were once constructed of wood and had exposed tile roofs, allowing warm air to circulate freely upwards. This ensured that the barrels were kept in the summer months at a temperature of around 35-40 degrees Celsius, optimal for the vinegar’s aging process. Today, however, these temperatures are widely exceeded and it is therefore important to take the right precautions for the correct maturation of Balsamic Vinegar.

Why does Balsamic Vinegar of Modena suffer from extreme heat?

Subjecting the barrels to excessive heat means speeding up the alcoholic fermentation, which instead must be very slow in order to obtain a good product. Furthermore, a dangerous phenomenon occurs for Balsamic Vinegar of Modena, i.e. the crystallisation of sugars: the heat causes the water to evaporate too quickly and generates a sugary sediment, forcing the producer to remove it and adjust the Modenese black gold carefully, topping up and decanting. As if this were not enough, too high temperatures lead to a sort of simulated aging, i.e. a dense Balsamic Vinegar but absolutely poor in aromas.

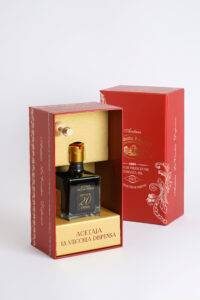

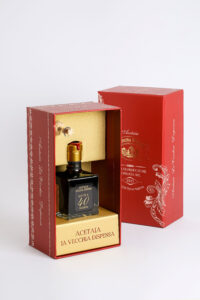

Now that you know the microclimatic characteristics of a real Balsamic Vinegar factory, you can venture inside and discover the production process: book now a guided tour and tasting of Balsamic Vinegar of Modena at “La Vecchia Dispensa” vinegar factory and take advantage of the spring period to delve into the unique experience of the aromas of Balsamico.